"Quick Stretch" -

Tensioning Procedures for Newman Roller Frames with 4 Rollers

be Stretch Devices, Inc.

1.- Frame Assembly: Unless your frames have been pre-assembled at the factory, begin by lubricating all the stainless steel bolts with C5A, a special copper-based anti-seize compound. Caution: Do not experiment with other lubricants as they will change the torque compression ratio and void the warranty.

How to Lubricate the Bolts: Put a small quantity of C5A on a piece of plastic.

Using a narrow brush, apply a moderate coating of C5A to the threaded part of each bolt, using only enough to change the surface color from silver to copper.

Corner Assembly: Place a metal washer on each bolt, followed by a plastic sealing washer. Assemble each corner to the rollers, as shown.

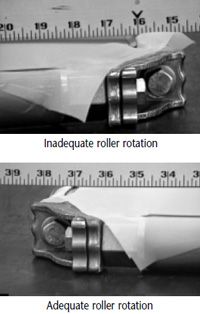

2.- Indexing the Rollers: Rotate each roller so that the outside of the t-slot (closest to you) is aligned with the second mark on the “inside” top of corner surface.

Secure both bolts of one roller before proceeding to its opposite roller, locking down each bolt using a torque wrench.

For model MZX™ frames, set torque wrench to 45 ft. lb. For model M3™ and model M6™ frames, set torque wrench to 55–75 ft/lb., depending upon tension levels. The higher the tension, the higher the torque setting; this keeps the frames flat and square. Repeat this procedure on the opposite roller. Complete frame set-up by locking down the bolts for the remaining two rollers.

Why the correct tools are important: Bolts are secured with a torque wrench (not just a basic ratchet wrench). This assures that the same locking force is applied to each bolt, keeping the corners parallel to the table and the frame flat.

SDI Torque Wrench: This highest grade industrial torque wrench has a ½" drive, direction change lever/button and an audible (click) type action. The “click” signals the operator to stop moving the torque wrench against the bolt when the appropriate torque level has been reached. Moving the direction change lever/button of the torque wrench to the right will allow you to tighten the bolts. Moving it to the left will allow you to loosen the bolts. When not in long term use, set torque wrench to lowest rating on the primary scale.

SDI Open End Combination Wrench: This magnesium alloy open end combination wrench is very lightweight, has an extended handle for better leverage and a wide grip claw for more surface area coverage on the end plug to assure longest life.

High Torque Socket: Our socket is a special 12 point version with round lobes and can sustain three times the amount of stress on the head of the bolt without failure. The 12 points also aid the operator in finding a convenient placement for the socket.

The Newman ST Meter™: Model 1-E is an industrial grade measuring device traceable back to the U.S. National Institute of Standards and Testing, in Washington, DC. It is the only tension meter in the world with all six hardened stainless steel gears, a shock-proof industrial gear movement and all jeweled sapphire bearings. Accuracy produced is plus or minus 1% across the full scale. (Other mechanical meters have only two soft brass gears and bushings, greatly reducing their shock-resistance, long term accuracy and life.) When not in use, lay the tension meter on its side, on its back, or return it to its box.

3.- Preparing the mesh: Cut the edge of the mesh and rip the remaining way across. This assures that the mesh is torn on a single thread and that it is straight. Do the same for one of the adjacent sides of the mesh. Leave approx. 2–3" of excess fabric around the entire outside dimension of the frame.

4.- Mesh Insertion: Always insert the mesh beginning with one of the 2 long rollers.

Roller (long) # 3: Lay the mesh over the frame and insert 2 Alignment Clips™ at each end of the t-slot, approximately 1” from where the end plug meets the tube portion of the aluminum roller.

Use the locking strip as a measuring device. Measure the fabric distance from the Alignment Clip™ to the “torn” edge of the mesh. Make this distance approximately equal on each end (using 2" to 3" of mesh overhang). Insert locking strip from right to left. With one hand, pull gently on the mesh against the Alignment Clip™, opposite the direction of mesh insertion. This assures that the thread alignment remains straight.

NOTE: The reason for measuring approximate equal distances at both sides of the roller is to have the threads parallel and perpendicular to each side of the frame and for the mesh to be positioned squarely in the frame.

Remove the Alignment Clip(s)™ when the locking strip reaches each clip. Do not slide or push the clips along with the locking strip!

Roller (long) #4: This is the roller opposite roller #3. Gently pulling the mesh toward you, insert 3 Alignment Clips™: one at each end of the t-slot, and the remaining clip in the center. Insert the locking strip, from right to left. (If while inserting the clips, you pull the mesh with too much force, the locking strip will not slide easily through the t-slot. If this occurs, remove the locking strip and reinsert the Alignment Clips™, pulling the mesh towards you using less force.) With one hand, pull gently on the mesh against the Alignment Clip™, opposite the direction of mesh insertion.

Remove the Alignment Clip(s)™ when the locking strip reaches each clip. Do not slide or push the clips along with the locking strip!

Roller (short) #1: Make sure this side of the mesh has also been “torn.” Gently pull on the mesh and insert only 2 Alignment Clips™ in the t-slot, one at each end, approximately 1” from where the end plug meets the tube portion of the aluminum roller.

Using the locking strip as a measuring device, measure the fabric distance from the Alignment Clip™ to the “torn” edge of the mesh, as you did on the first roller. Insert locking strip, from right to left. With one hand, pull gently on the mesh against the Alignment Clip™, opposite the direction of mesh insertion.

Remove the Alignment Clip(s)™ when the locking strip reaches each clip. Do not slide or push the clips along with the locking strip!

Roller (short) #2: Gently pulling the mesh toward you, insert 3 Alignment Clips™, one at each end of the t-slot, and the third clip in the center. Insert locking strip, from right to left, proceeding as before.

(Remember, if while inserting the clips, you pulled the mesh with too much force, the locking strip will not slide easily through the t-slot. If this occurs, remove the locking strip and reinsert the Alignment Clips™, pulling the mesh towards you using less force.)

Remove the Alignment Clip(s)™ when the locking strip reaches each clip. Do not slide or push the clips along with the locking strip!

5.- Softening the corners: Before tensioning, be sure to pre-soften the corners! This will prevent the mesh from tearing during the stretching process.

a.) Cut the plastic yellow softening tool to the same size as the diagonal of the corner of the frame, rounding the corners of the cut side to prevent a sharp edge from tearing the mesh. This will be the correct size for this frame model.

b.) Using a marker, draw a reference line against the interior edge of the t-slot, approximately 3" long, at both ends of all four rollers, for a total of 8 lines.

c.) Place the corner softening tool up against the corner of the frame, positioning it where the end plug meets the corner. Carefully place an Alignment Clip™ in the t-slot at the far end of the softening tool, using it as a measuring guide. The clip assures that only the stress concentration zone of the mesh will be softened, allowing for the greatest possible printing image size. Repeat this procedure on both sides of the corner.

d.) Beginning with any corner, and with the corner softening tool in the t-slot, press down on the inside edge of the locking strip. Gently rock the tool back and forth. Move it up and down as if you were cutting carrots, while maintaining a pivot point at the Alignment Clip™ in continuous contact with the mesh. At the same time, with the thumb or 2 fingers of your other hand, push down on the mesh with constant pressure until the mesh touches the table.  Release approximately equal amounts of mesh from each roller, on each side of each corner. This serves as an initial corner softening guide. Actual distance will depend on mesh count and final tension level. Do this same procedure to the other side of the same corner.

Release approximately equal amounts of mesh from each roller, on each side of each corner. This serves as an initial corner softening guide. Actual distance will depend on mesh count and final tension level. Do this same procedure to the other side of the same corner.

e.) Repeat this process with each of the remaining corners.

6.- Calibrating the Newman Tension Meter: Place the tension meter on the calibration glass which can be found in the meter box. The tip of the needle must be exactly aligned with the registration mark. If the needle is not in the correct position, loosen the lock on the upper right side of the meter face and rotate the rim of the face until the needle is correctly aligned. Retighten the lock.

With your fingers on the base of the tension meter, on either side of the dial face, check for any rocking motion on the glass that may affect the movement of the needle. If there is excessive rocking, or if it is necessary to rotate the dial face more than 15 degrees to correctly align the needle at the registration mark, the meter needs to be returned to the factory for recalibration.

7.- Tensioning the Mesh: Begin by consulting the mesh tensioning chart to determine initial tension level for your mesh. Be sure you are consulting the appropriate chart for the mesh type you are using.

Note: Stretch Devices provides two different mesh tensioning charts; one for standard high quality monofilament polyester fabrics (conventional mesh) and another for ultra high tension and low off-contact Newman Roller Mesh®. See full PDF for these charts.

Elevate the corners of the frame using four pieces of squeegee. This will permit free movement of the tools and keep the mesh off the table.

Begin with either of the short rollers, calling it roller # 1. Use the torque wrench to loosen each bolt of this roller two turns.

Note: The end plug is in the shape of a hexagon, consisting of six flat faces. Each flat face represents one hex, or 1/6 of a turn.

Place the SDI open end combination wrench on the end plug, with the wrench perpendicular to the roller.

With your hand at the top of the open end wrench, rotate the end plug one flat face, or 1/6 of a turn. Keep your hand in this position on the open end wrench. Use the torque wrench in your other hand to re-torque first the bolt on this side of the roller and then the bolt on the other side of the same roller.

Continue with the second short roller, calling it roller #2. Before using the torque wrench to loosen the second bolt on this roller, be sure to place the SDI open end combination wrench on the end plug with wrench perpendicular to roller (see photo, page 5) to prevent the roller from rotating backwards.

With your hand at the top of the open end wrench, rotate the end plug one flat face, or 1/6 of a turn. While maintaining this position with the open end wrench, use the torque wrench in your other hand to re-torque first the bolt on this side of the roller and then the bolt on the other side of the same roller.

Continue with roller #3. Place the tension meter in the center of the screen. The arrows on the base of the meter should be pointing between rollers #3 and #4, in order to correctly read the screen tension generated when roller #3 is rotated.

Unlock the bolts with the torque wrench. Use the SDI open end combination wrench to rotate the roller until you have a reading of 50% of the initial tension level on the dial face of the tension meter. Re-torque the bolts, as before.

Finish with roller #4. Tension the mesh to 100% of the initial tension level.

With the tension meter still in the center of the screen, turn the meter 90 degrees, with the arrows on the meter base pointing between the short rollers #1 & #2. Verify that the tension levels are equal in both directions, with a difference of no more than 2 N/cm between them. It is not necessary to undo the fabric and start over if the tension varies more than 2 N/cm because when it is time to re-tension the screen, the direction that is lowest will be the only side turned.

However, based on these readings, you may want to increase or decrease the rotation for rollers #1 & #2 accordingly, for your next screen. In this way, all of your mesh counts will have a specific calibration and can be documented in writing for future use. (See full PDF for Mesh Calibration Chart)

IMPORTANT: Check tension not only in the center of the screen but throughout the print area of your screen, making sure to include the outside corners. Check both directions of the mesh. You are looking for consistency within 2 N/cm. If this is not the case, the only way to correct the problem is through more careful and precise mesh insertion.

After Completing the Initial Tensioning Process: Using a marker at one corner of the mesh, write the mesh count and indicate the time and tension level now.

8.- Verifying that the frames are flat: Elevate the frame using pieces of squeegee below each corner. To check if the frame is flat, use your hands to tap lightly across the diagonal corners for any rocking movement.

In this photo: The left corner is elevated. The frame is not flat. Go to the corner diagonally opposite the elevated corner and unlock one bolt.

To flatten the frame, put the SDI open end combination wrench on the end plug at the far right side of the roller, positioned at the lowest possible angle.

Placing your left hand at the far end of the SDI open end combination wrench, apply downward pressure, until the corner previously elevated is now flat, and relock the bolt. The downward pressure on the roller will true the frame to the table top used for tensioning. The roller will not turn during this flattening process because the bolt on the other side of the roller is still torqued and locked. If excessive pressure is applied to the open end wrench, the corner on the other side of the roller will rise.

When the frame is flat, maintain constant pressure on the SDI open end combination wrench. Lock the bolt once again with the torque wrench. Now you can be assured that the frame is as flat as the surface used for tensioning.

To verify if the tensioning surface is flat: With the 4 corners of the frame simultaneously touching the table, rotate the frame 90 degrees. If the 4 corners are still touching the table, the tensioning surface is flat. Check several locations to verify if the entire surface is flat.

9.- Re-tensioning the mesh: (Wait a minimum of 20–30 minutes between re-tensionings.) Place the tension meter on the mesh in the center of the frame. Check the tension level in both directions of the mesh.

9.- Re-tensioning the mesh: (Wait a minimum of 20–30 minutes between re-tensionings.) Place the tension meter on the mesh in the center of the frame. Check the tension level in both directions of the mesh.

If in one direction, the tension is lower than in the other, this determines the direction that requires re-tensioning. Once making this determination, choose the roller that has been turned less.

VERY IMPORTANT: Before re-tensioning, always check the corners to see if they require additional softening. Only the corners nearest the roller to be turned need to be soft.

If necessary, they can be post-softened at this time.

Once again, place the tension meter on the mesh, in the center of the frame, to read in the direction you will be re-tensioning. Turn the roller until you reach the next tension level determined by the appropriate mesh tensioning chart, or to a level determined by you, for your specific shop requirements. This same procedure can be followed for subsequent re-tensionings.

Meter Stall: When determining tension levels for any given mesh count, it is important not to exceed the elastic memory of the polyester fibers.

During tensioning, you can see a direct relationship between the movement of your hand on the open end wrench and the movement of the needle on the tension meter. As you continue to move the wrench, you will reach a point where the needle on the tension meter appears to hesitate, or stall. Do not continue tensioning the mesh beyond this level!

During tensioning, you can see a direct relationship between the movement of your hand on the open end wrench and the movement of the needle on the tension meter. As you continue to move the wrench, you will reach a point where the needle on the tension meter appears to hesitate, or stall. Do not continue tensioning the mesh beyond this level!

If you continue tensioning the mesh past this point, the needle on the tension meter will begin to move again but you will have taken the mesh past the stall point and are likely to experience premature mesh failure.

While checking for meter stall, be sure that the bolts on the roller that you are turning have been loosened enough so that they do not lock up and give you a false stall point.

Newman Roller Frame® Mesh Calibration Chart. With this form you can record the calibration data (starting position, roller rotation, etc.) for each frame size and mesh count, to have a permanent tensioning record for reference and training purposes. (See the full PDF for this chart.)

Note: After you have completed tensioning your frame, each roller must be rotated a minimum distance, to avoid the printing problems that would be created by unequal off-contact distances. The interior edge of the t-slot must be turned at least as far as the first line on the inside top surface of the corner.

Preparing the Stretched Frames for Use

Trimming the Mesh: After final tensioning or re-tensioning of the mesh, you will want to trim the excess mesh down to 1" (2–3 cm), except in the area around the corners. In the area closest to the corners you will want to leave additional mesh (cut here on an angle away from the roller). By trimming the mesh in this way you can be certain to have enough mesh available at the corners to permit post-softening of the corners during future re-tensionings.

Trimming the Mesh: After final tensioning or re-tensioning of the mesh, you will want to trim the excess mesh down to 1" (2–3 cm), except in the area around the corners. In the area closest to the corners you will want to leave additional mesh (cut here on an angle away from the roller). By trimming the mesh in this way you can be certain to have enough mesh available at the corners to permit post-softening of the corners during future re-tensionings.

Taping the (inside of) the Frame: Stretch Devices makes available 2 different specialty tapes used for taping the inside of the Newman Roller Frame®. When used in conjunction with the Newman Roller Frame®, both of these tapes allow the printer to take advantage of the mesh flexing from the outside of the frame, maximizing free mesh area and minimizing print distortion and increasing usable print space. Regular tapes restrain the mesh during printing, reducing the free mesh area to the inside dimension of the Newman Roller Frame®.

The Newman Split-Liner Solvent Resistant Tape is available in a clear polyester or brown polypropylene and both offer superior adhesive structures. This tape was designed with a dual purpose. It can be used on the inside edge of the Newman Roller Frame® as a free floating ink dam, or in the center of the frame to separate 2 different inks.

To apply, remove one side of the split-liner from the half of the tape that will adhere to the mesh. Leave the other side of the liner intact on the vertical leg of the tape, directly in front of the roller or box beam. The tape and mesh are then free to move up and down with the squeegee.

To apply, remove one side of the split-liner from the half of the tape that will adhere to the mesh. Leave the other side of the liner intact on the vertical leg of the tape, directly in front of the roller or box beam. The tape and mesh are then free to move up and down with the squeegee.

Newman Roller Tape™ is a liner-less version of the original split liner tape. The Purple Roller Tape is a softer, more elastic, inert polyethylene substrate with a more aggressive adhesive. The Teal (Green) Roller Tape is a stiffer, less elastic, inert polyethylene substrate with a more aggressive adhesive. This tape is unique in that the center section of the tape has no adhesive. The top section of the tape has a thin band of adhesive that attaches continuously along the top of the roller, blocking all ink seepage along that edge, while still providing a minimum of adhesive contact for both quick release and some stretching ability (allowing unrestrained mesh movement during the squeegee stroke). The bottom section has a wider band of adhesive that applies directly to the mesh.

After cutting the tape to the correct size for the inside of the frame, apply the bottom section with the wider band of adhesive to the mesh first, as close to the roller as possible. Tuck the center section (without adhesive) in between the mesh and the roller. The top section of the tape is then applied directly to the roller.

After cutting the tape to the correct size for the inside of the frame, apply the bottom section with the wider band of adhesive to the mesh first, as close to the roller as possible. Tuck the center section (without adhesive) in between the mesh and the roller. The top section of the tape is then applied directly to the roller.

Because no adhesive is in direct contact with the roller, free mesh area will be maximized, print distortion minimized and usable print area will be increased.

The choice of which tape is best for your printing application is determined by personal preference. You will need to determine which adhesive offers superior resistance to your ink and which tape is easiest to use during application.

With any of these tapes, be sure to burnish down that part of the tape that comes in direct contact with the mesh to assure a good, positive seal. These tapes are easy to remove after the print run is complete. After reclaiming, apply tape again before the next print run, after re-tensioning.

With any of these tapes, be sure to burnish down that part of the tape that comes in direct contact with the mesh to assure a good, positive seal. These tapes are easy to remove after the print run is complete. After reclaiming, apply tape again before the next print run, after re-tensioning.

Newman Fabric Protectors™ are plastic covers that fit around the roller or box beam to protect the mesh. They are impervious to solvents and inks. They simply slip on the roller or box-beam and are held in place by tape.

Clamping into Press or Hand Table:

Clamp Adapters for the Newman Roller Frame® are available and recommended for a wide variety of frame models. The adapter conforms to the roller on the inside and presents a flat clamping surface on the top. Where required, they assure positive lock-down of the frame into the press or hand table.

On an MZX™ frame with square bar, when used in a hand table with hinge clamps or with a rear clamping machine, the square bar provides a direct clamping surface. No clamp adapters are needed. This model frame has no rear corners which provides excellent front end stability as well as rigidity for raising and lowering.

No clamp adapters are needed in machines outfitted with Newman Pin-Registration System Level 1A Frame Clamping Channels with Frame Clamping Air Bars.

No clamp adapters are needed with box beam frames.

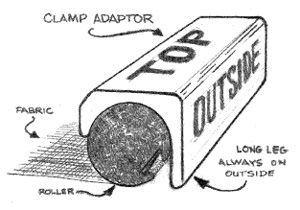

In a side clamping machine, or front to rear clamping machine, generally 4 clamp adapters are required per print head. The long leg of the clamp adapter must be to the outside to lock effectively. The clamp adapter provides a flat area for the swivel pad to bear onto, which in turn, transfers its load to the roller.

The illustration provided below provides a close-up view of a clamp adapter in the correct position over the roller. When loading the frame into position place clamp adapters on the roller approximately positioned where the swivel pads will be. Once clamped into place, the frame is positively locked.

The illustration provided below provides a close-up view of a clamp adapter in the correct position over the roller. When loading the frame into position place clamp adapters on the roller approximately positioned where the swivel pads will be. Once clamped into place, the frame is positively locked.

REMEMBER: You are using a re-tensionable Newman Roller Frame®. The primary function of a re-tensionable frame is to work-harden and stabilize the mesh in order to provide you and your customers with consistent, reliable, repeatable results. Utilize the frames in this manner to achieve superior registration, productivity, and rapid R.O.I. (return on investment) for this most important of all quality control printing tools.

TO OBTAIN THE MAXIMUM BENEFITS FROM YOUR RETENSIONABLE NEWMAN ROLLER FRAMES®: we recommend reclaiming your mesh and repeating the process of re-tensioning after each production run if the tension has dropped more than 2N/cm.